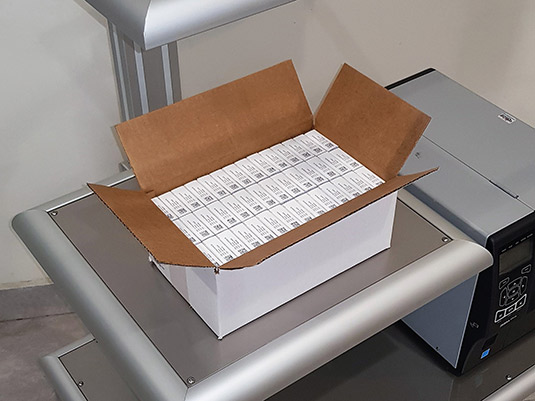

Its operation is based on placing the box or pack on the base of support with the codes printed up to capture the image that will be processed by the vision program; detecting the contents of each code automatically and performing the aggregation to the later stage.

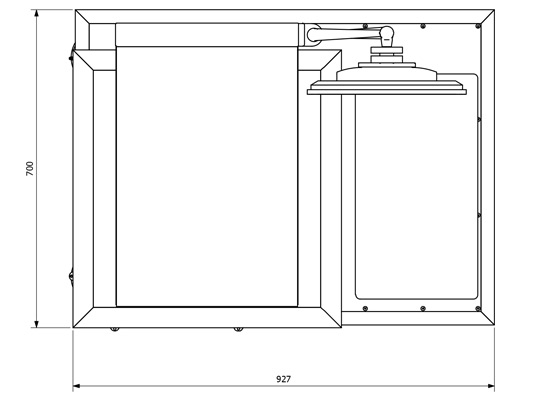

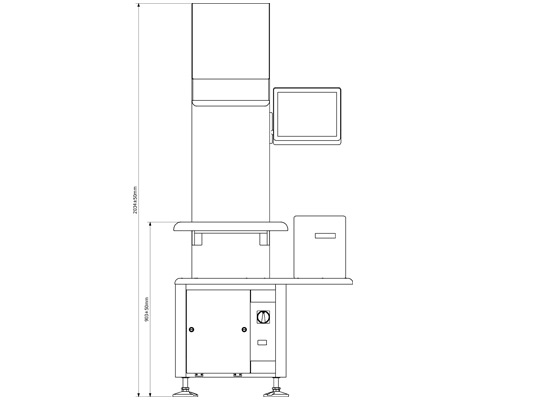

It is characterized to be an equipment of very small dimensions. Has a reading surface of 400 mm x 400 mm. At the top has a high definition camera of German manufacturing that allows has an optimal reading of multiple 2D codes DataMatrix of each layer to aggregate.

A square of high power leds illuminators collaborates to obtaining the high quality image.

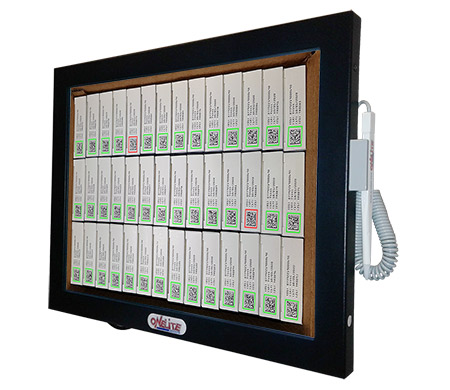

The ONELITE vision system for the processing of productions orders allows by means of the network communication with the system print and check the aggregation only the serials that was inspected in the previous stage, automatically rejecting duplicate or non-compliant serials.

Facilities provided by the system:

- Make drug inquiries during the process.

- Give off units definitively.

- Give off units for samples, indicating the destination of the same.

- Unadd packages, boxes and pallets.

- Give off packages, boxes and pallets definitely.

The base of support for boxes or packs is adjustable in high. It provides a comfortable position to charge the cases in the box. In addition to that, the panel control with a 15” touchscreen ensures an ergonomic position for the operator.