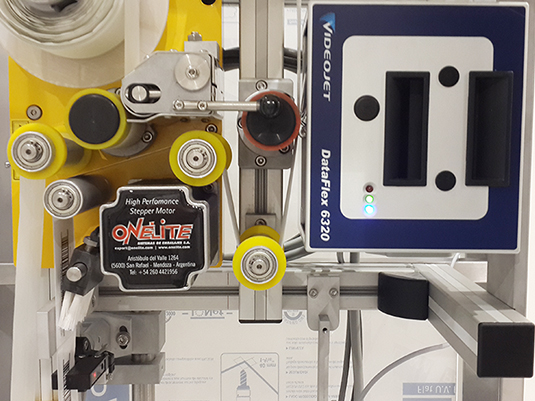

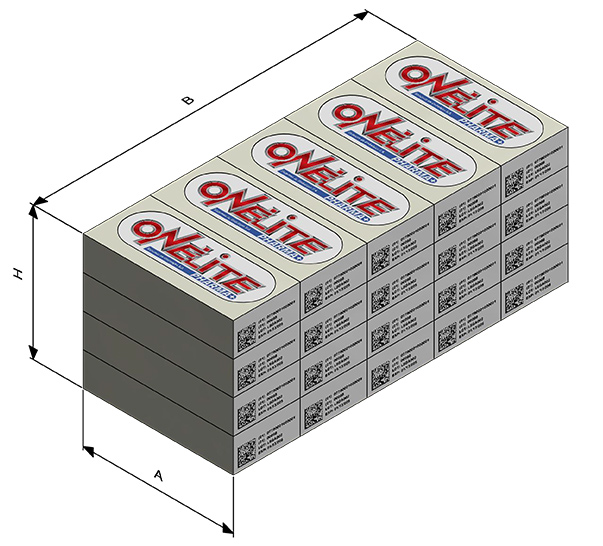

It can incorporate a Thermal Transfer Printer to create bar codes, traceability data (e-pedigree) and variable information (lot, elaboration date, expiration date, etc.). As a security measure, a Code Reader or an Intelligent Vision System for reading and checking print data is installed.

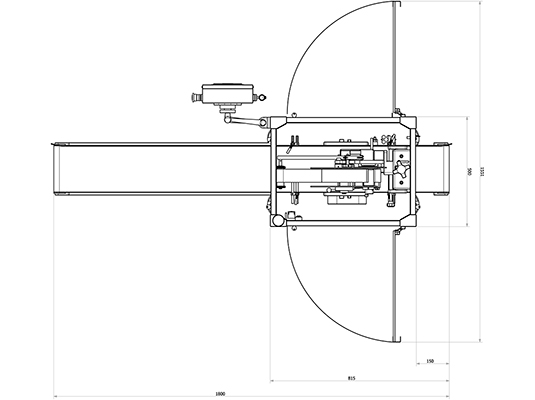

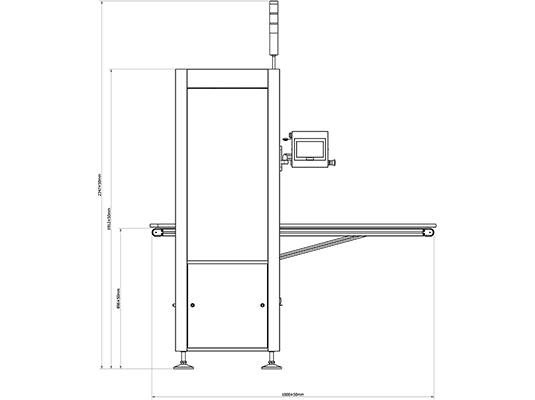

The labeling head is mounted on a double-column vertical adjuster, moved by an adjusting wheel, in order to achieve the height needed for each different product pack.

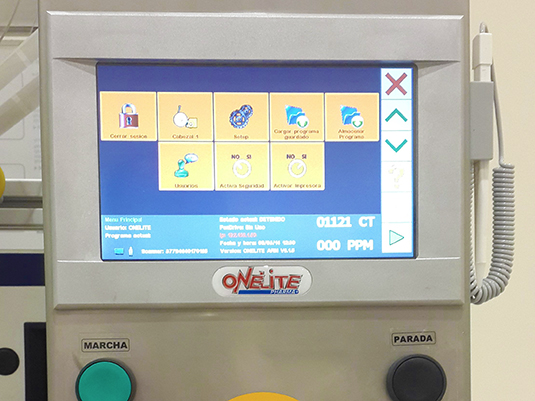

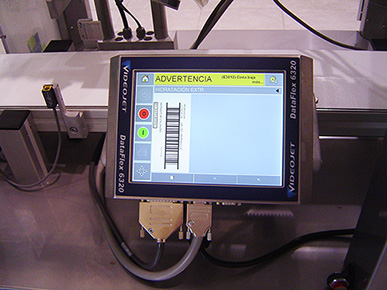

The equipment PLC incorporates a 7” Touch Screen HMI to visualize information, operations, regulation parameters and alarms, as well as to create/recover stored programs of determined products.

This machine meets the stringent requirements of the pharmaceutical industry given that it is operated by a programmable logic controller fulfilling all the requirements of the GAMP5 guidelines.

Optionals

THERMAL TRANSFER PRINTER: A printer of high quality digital technology creates clear codes easy to read. This printer can be set to print automatically and in real time date and time. It has a full color touchscreen interface, where you can select a printing program or introduce specific data in the fields provided to this end.

BARCODE READER: A verification module in order to check codes in the labels, using a laser scanner or an optical sensor. If a code is unreadable or incorrect, this module detects it, the machine stops immediately, an alarm appears in the screen and a sound and light signal is activated.