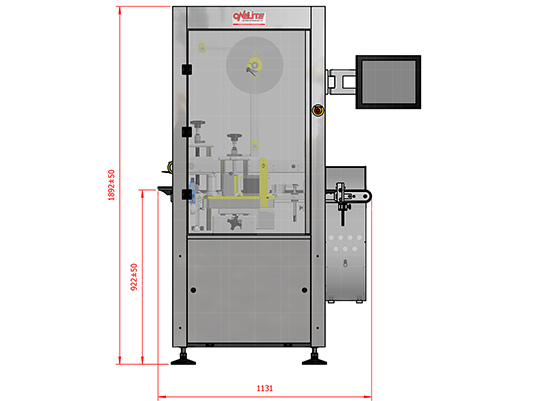

ONELITE Serialization module

The system can process batches of different drugs creating univocal codes for each unit (random or sequential order), as recommended by GS1 standards. At the same time a database is created, saving traceability information, restricting access with user levels in accordance with 21 CFR Part 11 (FDA).

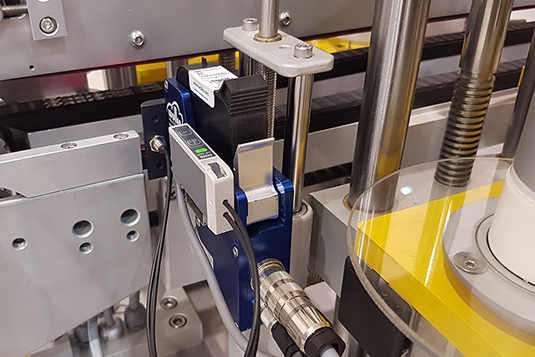

The ONELITE serialization equipment incorporates InkJet thermal transfer printer, capable of printing alphanumeric digits as well as linear and 2D barcodes like GS1 DataMatrix mainly for pharmaceutical application.

The machine is equipped with an artificial vision system to perform verification of printed information, by quick capture of images, using lenses with vision tools for 2D and OCR (Optical Character Recognition) codes, and integrated lighting. It is also possible to carry out safety verification by crossing obtained data between human readable texts and 2D codes to ensure data integrity.

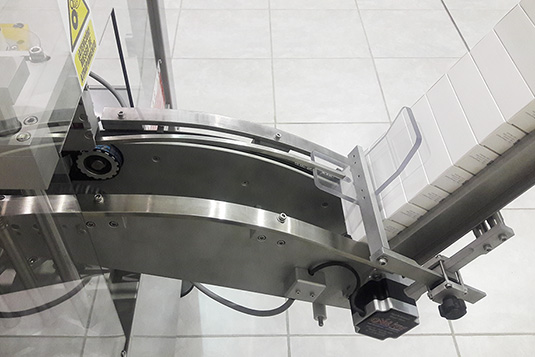

Mechanically, the equipment has a main double conveyor and an upper conveyor, both adjustable for a great variety of carton sizes, assuring a proper movement of the product, free of vibrations, in a wide range of speeds. At the output of the machine, a pneumatic ejection system removes any unlabeled or incorrectly printed carton to a rejection drawer, provided with by an input sensor.

The AR-BOX EPC requires minimal space for emplacement and installation, allowing easy operation thanks to a 15-inch touch screen, coordinating all the processes together (labeling, printing and verification, rejection and data storage).

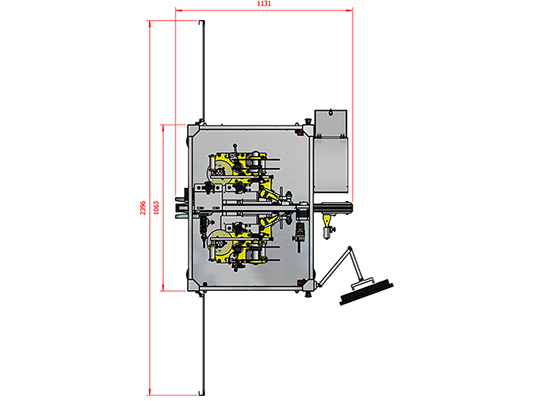

OPTIONAL: Feeder

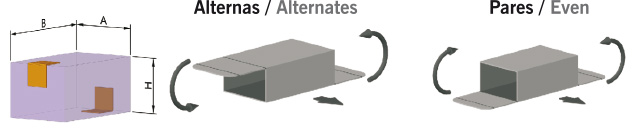

Optionally the AR-BOX EPC can be constructed with an automatic feeder.