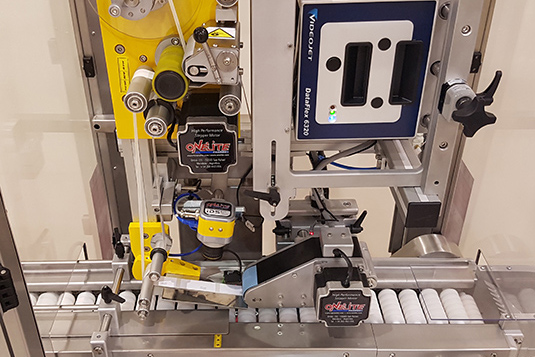

The equipment includes the codification and verification system by OCR (ONELITE Print and check module). Provided with industrial thermal transfer printer, allowing the OCR printing on labels before application; an inspection camera for the verification of printed information and the rejection station for the labeled products with misinformation. Loading of products is manually at the income of the machine as well as the outcome when the product is processed.

The AR-FARMATUB requires minimum space for placing and functioning and also offers an easy way to operate by the HMI control panel 15” touch screen which coordinates the machine and the labeling, printing and verification system, obtaining a central database for the backtracking of every product. It allows saving programs with the specific configuration of every product, user administration based on user levels with different access level always username and password required, registry of events, maintenance options on screen and backup system in line with CFR 21 part 11 (FDA) and GAMP5 (ISPE).

PhC Cosmetics / Pharma Line: AR-FARMATUB

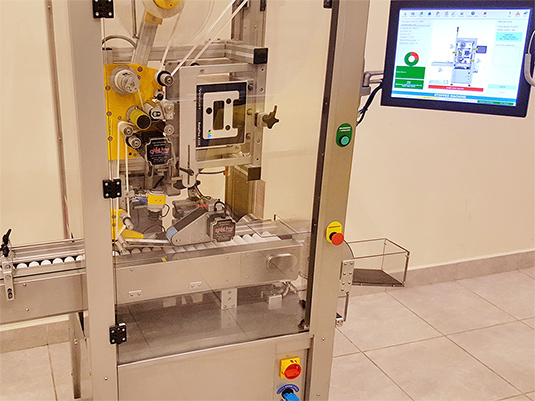

Labeling machine for vials with print and check system AR-FARMATUB.

Automatic labeling machine with manual feed for the application of self-adhesive labels on cylindrical products (vials and syringes) in horizontal position. This labels can be printed and verified in the same equipment including a rejection station for non-valid units.

Details Gallery

AR-FARMATUB Detail

AR-FARMATUB Detail

AR-FARMATUB Detail

Outstanding Features

- Provides complete coordination between the camera, print head, labeling and rejection control.

- Simple adjustment for placing the labeling head for a variety of vial sizes.

- Quality control of computerized system according to guidelines given by GAMP5 (ISPE) and 21 CFR Part 11 (FDA).

- Automatic syncronization of speed for engines in continuous mode.

- Single characters of overprint control system OCR (Optical character recognition).

- Rejection station for labeled vials with misinformation.

- Minimum space required.

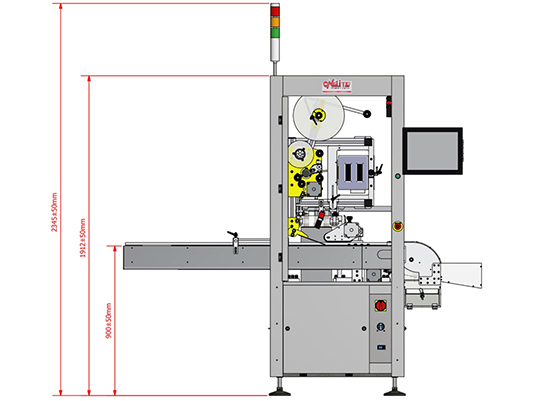

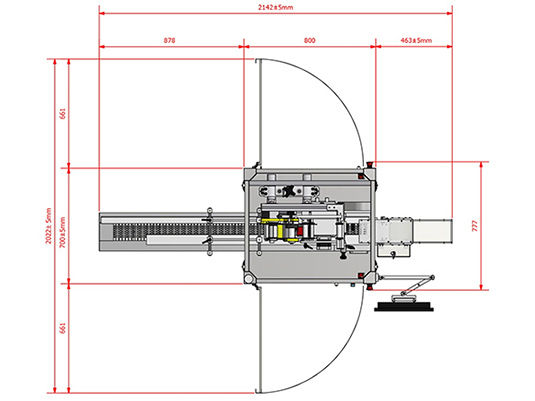

Actual Dimensions

Front Layout

Upper Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 2145 x 780 x 2345 |

| Weight (kg) | 350 |

| Installed Power(KVA) | 2 |

| Air Pressure (bar) | 6 |

| Noise level (dB (A)) | ≤ 80 |

| Production Capacity (cases / hour) * | 10.000 |

| Speed Range (meters/minuto) * | 2 - 6 |

| Permissible products: vials (mm) - Diameter x Height | 14 - 26 x 38 - 65 |

| Permissible products: syringes (mm) - Diameter x Height | 14 - 16 x 60 - 100 (alas 6mm) |

| Admisible labels (mm) - Height x Width | 15 - 75 x 25 - 60 |

| Printing area (mm) | 32 x 68 |

| Printer | Thermal Transfer Overprinting (TTO) Thermal Inkjet (TIJ) (Optional) |

| Camera | High resolution |

| * The equipment speed is adjustable reaching maximum production of 10.000 units/hour, but it will be limited to the feeding speed by the operator since is manual loading. | |