The equipment is suitable for the application of labels wrapping around the container or covering half of it, with a perfect alignment. Thanks to the smoothing system, the label sticks without bubbles or wrinkles.

From the command panel you can activate and configure the labeling head, configure the settings of the centering pushing rolls, indicate the container size and the label position, activate the printer (if you have the option), among others.

The machine counts with a Login session with different user levels.

Bedplate

The bedplate and structure is made of carbon steel, welded and protected with powder electrostatic painting, coated with stainless steel AISI 304, firmed on four adjustable-height legs.

Conveyor

It is formed by two plastic chains, with stainless steel laterals and double side guides of adjustable width.

Labelling head

The labeling head is the devise dispensing the self-adhesive label. The same is driven by a stepper motor and controlled by a microprocessor.

Container spacer

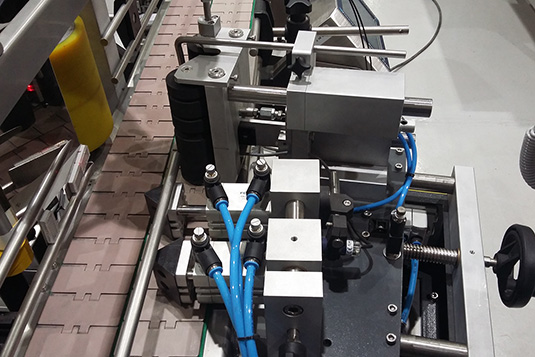

The machine has a container spacer that works between two pneumatic locks, producing the right distance between containers and preventing the entry of an extra container during the labeling process.

ABQ Food / Beverage / Chemical Line: SR-92 AR

Labeling machine with rail for handle for the application of self-adhesive labels

on cylindrical containers (cans or buckets) SR-92 AR

It is an electro-pneumatic equipment, designed for the labeling of cylindrical containers with self-adhesive labels, applying them with the highest precision and a perfect positioning.

Details Gallery

Container spacer

PLC with 4.3" full color touch screen

Fast mechanical adjustment of height and width

Labels sensor

Centering pucher rollers

Outstanding Features

- PLC control system with 4.3´ touchscreen, providing an easy operation.

- Fast mechanical adjustment of height and width for a quick adaptation to different case sizes.

- Container spacer working in synchronism with the machine rate.

- Adjustable operating speed by a single parameter on screen.

- Minimum spice required.

- Adequate safety for the operator and the working environment.

- Stepper motors that produce greater precision in the operation on the moving parts.

- Printer: optionally a TIJ or a TTO printer can be installed on the machine for the print of legends, logos, barcodes, date and time on real time, covering an area of 32mm x 40mm. (there are other models for the printing of bigger area).

- Blower: it is a device designed for the labeling of bigger containers (4 L/1 Gal). The purpose of this device is to avoid the sticking of the label to the container, before it touches the drive roller. In this way, it eliminates the possibility of wrinkles or folds in the label.

- Handle rail: Its function is to keep upright the handle during labeling, preventing it to fall causing damage to the machine parts.

Optionals

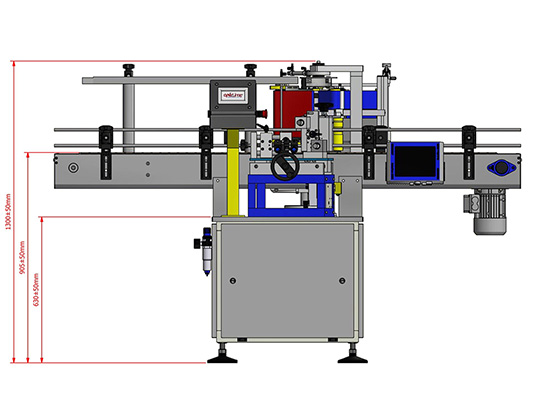

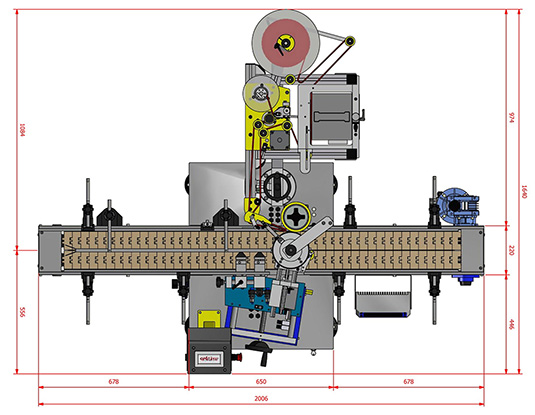

Actual Dimensions

Side Layout

Upper Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 2006 x 1640 x 1300 |

| Weight (kg) | 300 |

| Installed Power (KVA) | 2 |

| Noise Level (dB (A)) | ≤ 70 |

| Conveyor Speed (m/min) | 21 |

| Production Capacity (containers / minute) | 1/4 y 1/2 liter: 52 1 liter: 46 4 liters: 14 |

| Admissible container size (mm) - Diameter x Height | 70 -170 x 55 - 215 |

| Admissible label sizes (mm) - Lenght x Width | 15 - 195 x 40 - 490 |