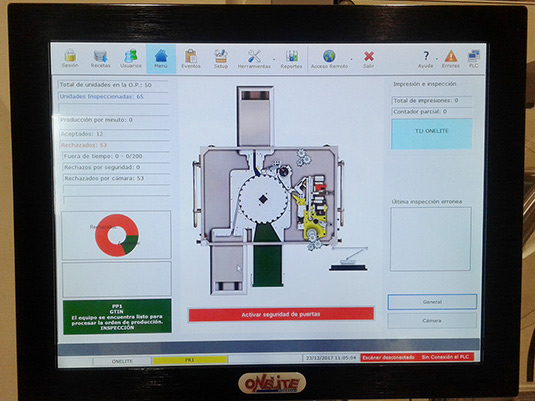

The equipment includes the codification and verification system (ONELITE Print and check module). Provide an industrial thermal transfer printer (TIJ) and an inspection camera, which allows print and verify the OCR information on labels before its application on the products. Also provides a rejection station for the labeled products with misinformation. Loading and unloading of products are manual. The unloading of rejected products is manual too.

PhC Cosmetics / Pharma Line: VLM-7000

Labelling machine for vials with print and check system VLM-7000

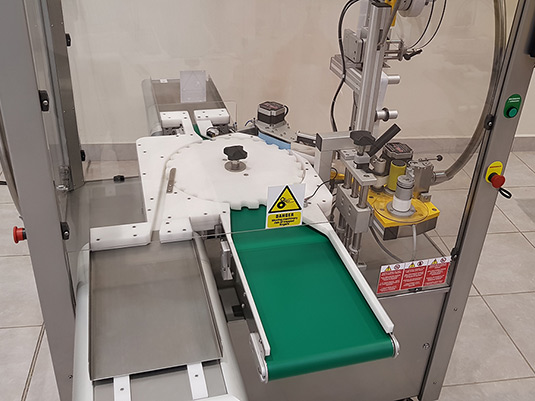

Automatic labelling machine for vials in vertical position with integrated print and check module.

Details Gallery

Integrated Print and Check System

Integrated Print and Check System

Mechanical adjustments with position indicators

Outstanding Features

- Provides complete coordination between the camera, printing head, labelling and rejection control.

- Simple adjustment for placing the labelling head for a variety of vial sizes.

- Automatic synchronization of speed for engines in continuous mode.

- Single characters of overprint control system OCR (Optical character recognition).

- Rejection station for labeled vials with misinformation.

- USB and Ethernet ports for transferring data with other equipment and downloading the Event Log.

- Labelling in vertical position system.

- Manual products loading and unloading using storage trays.

- Adequate safety system that guarantees reliable operation of the equipment, preserving the safety of the operator.

- Minimum space required.

- Quality control of computerized system according to guidelines given by GAMP 5 and 21 CFR Part 11 (FDA).

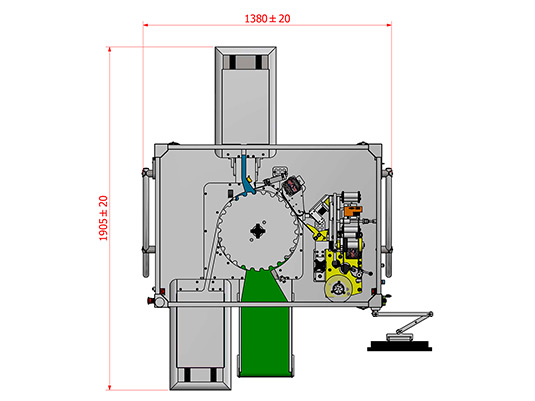

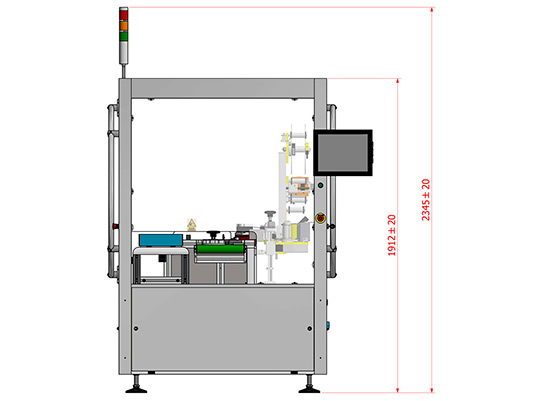

Actual Dimensions

Upper Layout

Front Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 1390 x 1900 x 2350 |

| Weight (kg) | 400 |

| Installed Power(KVA) | 2 |

| Production Capacity (vials / hour) * | 13.000 |

| Admisible products (mm) - Diameter x Height | 10,5-25 x 30-65 |

| Admisible labels (mm) - Height x Width | Máx. 70 x 15-60 |

| Inspection area (mm) | 12,7 |

| Printer | Thermal Inkjet (TIJ) Thermal Transfer Overprinting (TTO). (Op.) |

| Machine vision camera | High resolution |

| * You may need a central disk bit / ** Other diameters and heights per request. | |

The mentioned characteristics can be modified without prior notice if the Company considers it for manufacturing or operating reasons. Operation voltages can be adaptable to each country or working environment.

Aware of the need to maximize space in the clean rooms in pharmaceutical industry, the size of our machines is one of the main premises at the time of the design of our entire Pharma Line.

GET IN TOUCH! Take advantage of the knowledge of our Sales Team by calling us today on +54 260 442 1956 or from here . We will be happy to help you to come up with the most effective solution for your requirements.